Swiss Krono is the undisputed leader among manufacturers of wood-based materials. The company’s wide range of products includes OSB, furniture boards, laminate flooring and vinyl panels. The Group operates in many countries and employs nearly 5,000 people. Since its inception, the company has paid great attention to the sustainable use of resources In order to keep the consumption of raw materials as low as possible, it invests in energy-efficient solutions. The latest of these is the equipping of the Group’s Polish plant with modern LED lighting.

Project video

Watch the video prepared by our Key Account Manager – Marcin Łukasik

What are the benefits of investing in a lighting upgrade?

Reduced electricity consumption

Improved working conditions

Reduction of CO2 emissions

The choice of Luxon LED was mainly determined by technical parameters. In this case, it was most important for the customer to achieve the best possible improvement in energy efficiency, which was guaranteed by Luxon LED products.

Piotr Danielski

DB Energy

Compare the effects before and after – move the line in the middle of the photo

Time to replace luminaries, or the goals of the lighting upgrade at the Swiss Krono plant

The company is transforming a renewable raw material such as wood with an emphasis on energy-efficient process solutions. The long-term strategy is, among other things, to minimise the electricity consumption of the company’s operations. Therefore, modernising the lighting throughout the plant, in the production halls, offices and around, as well as equipping it with a control system, was one of the priority projects.

The key objective of the upgradeset by the investor was to use luminaries that improve working conditions. High working comfort and safety are the main priorities for the company. Therefore, lighting upgrade included also emergency lighting. In addition, it was also necessary to take into account the adverse influences on lighting. In the wood processing industry, machines of considerable size are used which generate large amounts of heat. Consequently, the luminaries operating around had to be able to withstand high temperatures.

The SWISS KRONO Group’s plants operate around the clock. For this reason, the customer required that the installation of the luminaries take place seamlessly during plant operations. To this end, a lighting audit was essential to create a precise work schedule.

New LED industrial lighting at SWISS KRONO – benefits

☑ Lighting system resistant to high temperatures and dust,

☑ improved employee comfort,

☑ improved occupational safety,

☑ energy-efficient light sources,

☑ trouble-free operation of the system,

☑ reduced CO2 emissions,

☑ matching lighting parameters in individual rooms.

Replacement process: challenges during design and installation of LED luminaries

Complex lighting upgrades are processes involving many steps. They are influenced, among other things, by the operating environment of the luminaries, the condition of the existing wiring and the way the plant operates. Analysis of the needs and the demanding environmental conditions, which include heavy oil fumes and high temperatures, are not the only challenges we encountered at SWISS KRONO facilities.

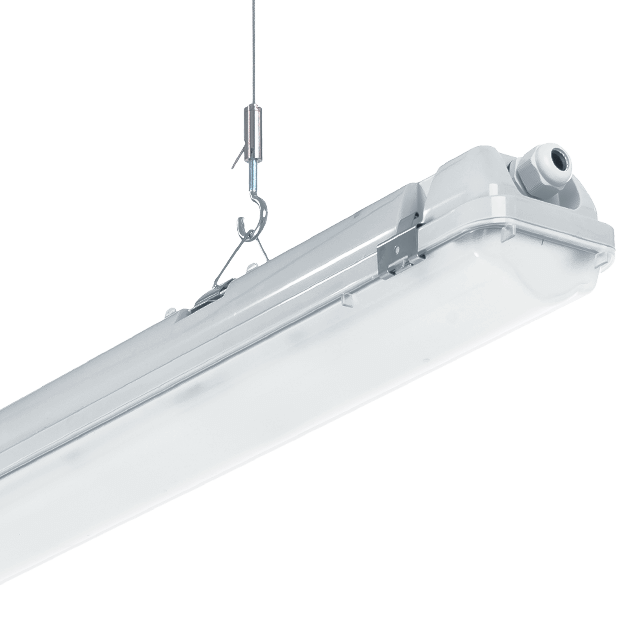

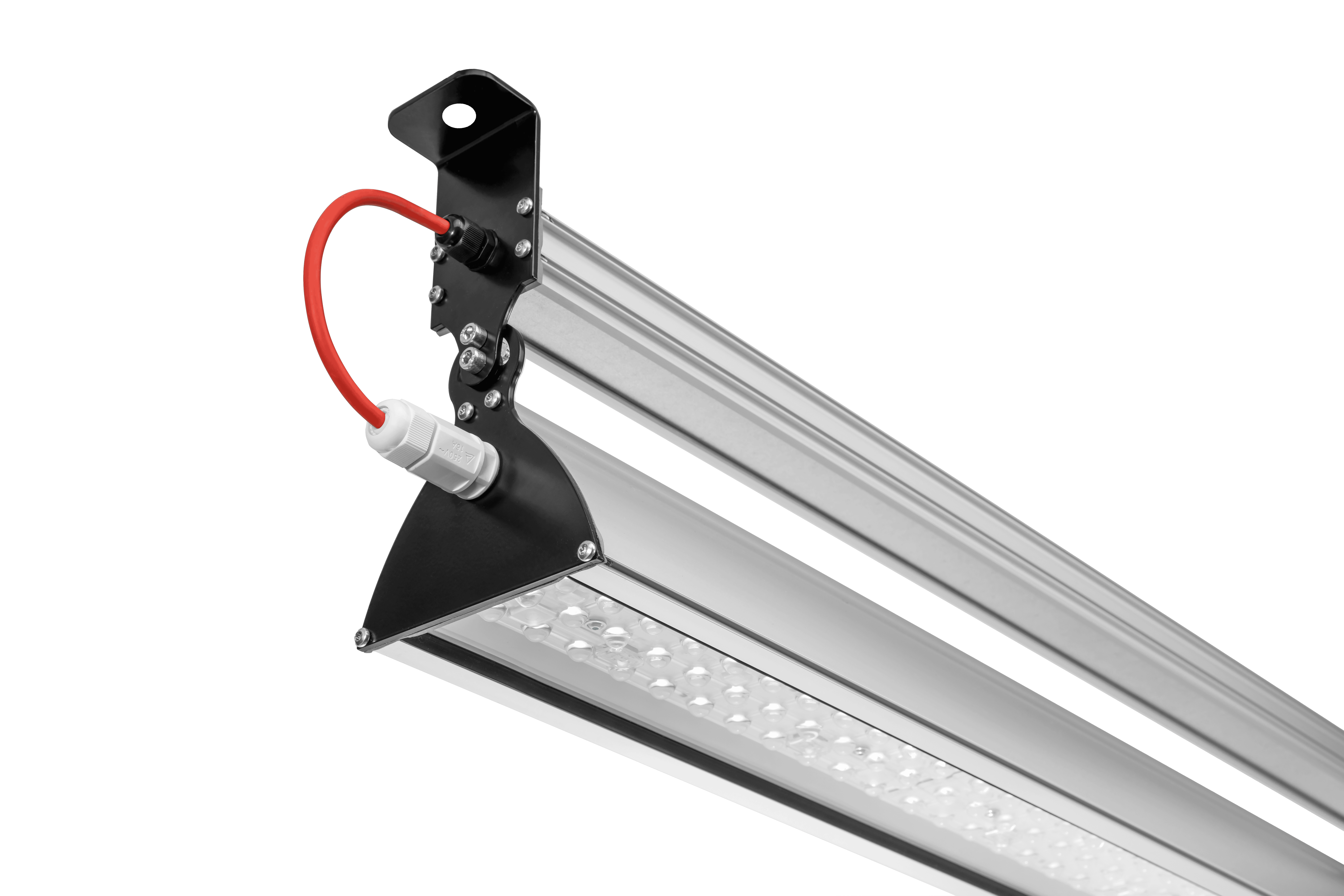

Due to the height of the production halls, the high temperatures and the difficult working conditions, it was not possible to install standard LED luminaries.. We offered the customer a tailored basic lighting solution based on dedicated light sources as well as emergency and office lighting adapted to the investor’s requirements. The condition of the existing wiring allowed the luminaries to be replaced on a 1:1 basis, which the lighting design also had to take into account. The new light sources were fitted with a lighting control system based on the DALI protocol. The installed motion detectors and light intensity sensors allow energy consumption to be minimised while maintaining the required operating conditions. Meanwhile, the zoning of the system and individual addressing of luminaries made it possible to adapt lighting operation to individual, sometimes changing needs.

We performed the lighting upgrade according to a work schedule which, due to the accessibility of certain areas of the production hall, had to be adjusted on an ongoing basis. It was necessary to adapt to the operation of the entire plant working 24/7.

Production halls are not the only places where new luminaries have been installed. We also carried out lighting replacement in the offices and outside areas of the plant. They were intended to improve working comfort, better visibility in the spaces surrounding the building, as well as significantly reducing the plant’s electricity demand.

New light sources for SWISS KRONO in figures

This project represents more than 5,000 new light sources made using LED technology.

- Primary lighting: 4392 luminaries,

- emergency lighting: 677 luminaries.

A wide range including primary, emergency and external light sources. We primarily used dedicated Ultima SWISS KRONO LED and Ultima LED HPTluminaires as well as Industrial LED, EDGE and Cordoba LED models.

Besides the advantages such as the reduction of carbon dioxide emissions and energy savings, the investor gained comfort in the use of lighting for years thanks to the 5-year warranty.

Marcin Łukasik

Key Account Manager

Harsh working conditions for luminaries mean not only high temperatures, but also the risk of mechanical damage. Therefore, dedicated solutions are sometimes required to achieve the goal of minimising electricity consumption.

Do you also want to replace the lighting in your company with energy-efficient LEDs? If you have any questions, contact us using the form below. We will prepare a free audit for you and show you the scale of the savings on LED.

See other Case Studies

Case study – Luxon and Indulux for the Grolsch brewery in the Netherlands

We have established cooperation with Indulux that included the delivery of LED luminaires to facilities belonging to Grolsch in the Netherlands. Reducing electricity consumption, caring for the environment and employees and the need to phase out fluorescent lamps were the main reasons why the company decided to replace its light sources.

New LED lighting for CIECH Soda Polska plants in Janikowo and Inowrocław

Ciech Soda Polska is Europe's second largest and Poland's only producer of heavy and light soda ash. The company operates in many market segments.

Masz dodatkowe pytania?

Zapytaj naszego eksperta