Ciech Soda Polska is Europe’s second largest and Poland’s only producer of heavy and light soda ash. The company operates in many market segments. These include chemical, glass, food and feed industries, as well as pharmaceuticals and the water treatment sector. With attention to development and, at the same time, caring for employees and the environment, the CIECH Group implements the ESG strategy. As a result, the plants in Inowrocław and Janikowo received new energy-efficient LED lighting.

Project video

See the video prepared by Michał Wyborski, our Sales Director

Benefits of LED lighting used in the manufacturing hall

of LED luminaires installed

electricity saved over the year

10-year warranty on luminaires

The upgrade of lighting was primarily intended to bring savings, thanks to LED luminaires, which are part of the CIECH Group’s wide-ranging action plan. This indirectly involves the reduction of carbon dioxide emissions into the atmosphere, and is directly related to our ESG strategy, which aims to reduce greenhouse gas emissions.

Tomasz Molenda, CEO CIECH Soda Polska

Objectives for replacing the lighting system at CIECH industrial plants

The ESG strategy of the CIECH Group is based on cornerstones that form the basis of the company’s operations. They are aimed, among other things, at reducing the adverse impact on the environment and caring for people, including the employees. The upgrade of lighting to LED industrial lamps was intended to contribute to the goal of saving electricity consumed in the Company’s facilities. The CIECH Group’s goal was also to reduce CO2 emissions, which fits perfectly with the idea of sustainable development. Investing in modern LED lighting was also intended to improve working conditions in the facilities. The safety and comfort of employees was improved both by the industrial luminaires located in the production areas and the light sources in the offices undergoing the upgrade.

In addition, one of the investor’s expectations was that the lighting upgrade would be implemented during the operation of the facilities. It was also important to provide support throughout the entire investment phase when auditing, designing and installing the lighting system. The installation process, on the other hand, had to be completed in the shortest possible time.

Upgrading to LED lighting in industrial and office areas – advantages

- Reduction in carbon footprint,

- energy efficiency, i.e. reduction in electricity consumption,

- high efficiency of light sources,

- improved facility conditions,

- increased employee safety,

- reduced failure rate of the lighting system,

- obtaining white certificates.

Challenges and the industrial and office lighting upgrade project

Production of chemical products is the main area of business in CIECH Soda Polska’s industrial halls. These are demanding areas. They are affected by, among other things, high temperatures, dust or airborne chemical fumes, which posed a challenge when designing the new lighting system. The new LED lamps had to be resistant to these conditions. To this end, even before the conception, we carried out a detailed audit that took into account all relevant aspects of the lighting upgrade. Based on that, we created a work schedule together with the investor, which also took into account the most challenging areas of production operations.

The industrial lighting in the halls in Janikowo and Inowrocław had to be installed during uninterrupted operation of the plants. In cooperation with ControlTec Sp. z o.o., we installed more than 14,000 LED based luminaires that way. Some of these required customised installation. To this end, the fitters used, among other things mountaineering techniques and were equipped with full-face masks with chemical filters. All this was done with all safety precautions in mind for both the installers and the production hall workers. Timeliness was also an important aspect during the project. Therefore, the lighting upgrade was carried out according to a predetermined schedule. In order to verify the progress of the work and solve current technical issues at the facility, a daily work acceptance report was signed and a quantitative report of the installed luminaires was prepared.

The lighting upgrade also included the plant’s office facilities and outdoor areas. The new light sources were intended to optimise the electricity consumed, as well as to improve employee comfort. For this reason, we installed LED office luminaires adapted to the needs of these areas.

What are the benefits of the industrial LED lights installed in Inowrocław and Janikowo?

- 10,000 MWh of electricity saved per year,

- reduction of 8,000 tonnes of CO2 emissions annually,

- rapid return on investment,

- reduction of lighting failure costs,

- implementation of the ESG strategy and the idea of sustainability,

- another step towards climate neutrality,

- obtaining additional funds from the sale of white certificates.

By the end of 2021, we had completed more than 9,000 lighting upgrade projects in Poland and Europe. Without a doubt, the upgrade in the Ciech Soda Polska plants in Janikowo and Inowrocław was the most impressive investment, not only because of the scale of the challenge, but also the effects. We replaced more than 14,000 luminaires at the two active plants in 6 months, which resulted in approx. 10,000 MWh annual energy savings and a reduction of approx. 8,000 tonnes of CO2 emissions. The project was part of the Ciech Group’s ESG strategy and fulfils its sustainability goals, but, with current energy prices, it was also aimed at cost optimisation.

Michał Wyborski Luxon LED Sales Director

Investment in new LED lighting in figures

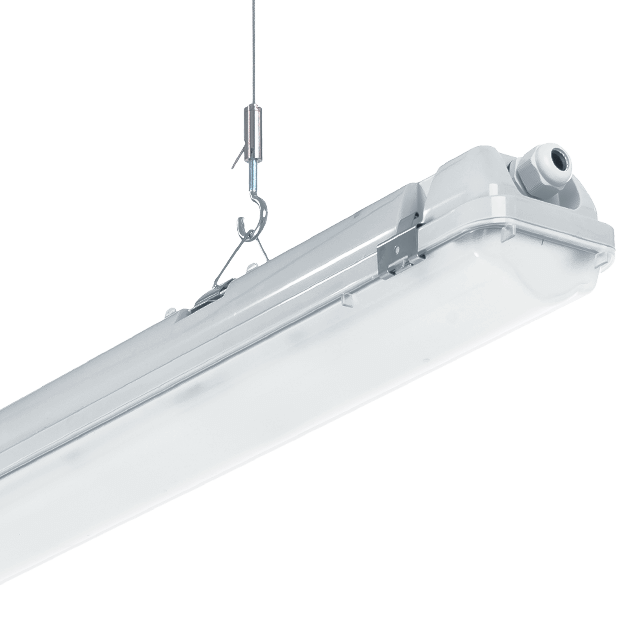

One of the most extensive industrial lighting upgrade projects in Poland involved the replacement of over 14,000 luminaires. The project covered both, the replacement of lighting in production halls and new light sources in offices and outdoor areas of both plants. We installed many types of LED luminaires including the Industrial LED, Edge LED and Cordoba LED. The project was overseen by four works managers who worked together with 16 installation teams. Reduced electricity consumption, improved safety and working conditions are the benefits of properly designed industrial LED lighting preceded by an audit. LED lamps are a good step into the future if you want to reduce your electricity bills.

Any questions? Ask our experts by filling in the form below.

Daniela Bicz

Doradca ds. efektywności energetycznej

See other Case Studies

Comprehensive lighting modernization for Dong Yang Electronics

Dong Yang Electronics is a Korean company founded in 1989. One of its headquarters is located in Poland. It's a manufacturer of plastic components for TV sets, particularly plastic housings, produced mainly for LG Electronics Polska. Luxon LED partnered with Dong Yang Electronics after having completed a previous order for the manufacturer.

Industrial lighting – Industrial:LED 5.0

Learn the process of creating Industrial LED 5.0 and the factors affecting the highest efficiency of the luminaire amounting to 185lm/W.