Since the 1990s, Zott has been manufacturing dairy products such as yoghurt, desserts, cheese, cream and cottage cheese. he company owns such brands as Monte, Jogobella and Smakija. Its production plant is located in Opole and products manufactured there are exported to over 75 countries around the world. In line with the development of the company, growing ecological awareness and new possibilities to save energy in production plants, Zott decided to use more effective, efficient and economical luminaires. Production halls require special illumination, because it is necessary to maintain low temperature to preserve the freshness of the products, and to meet the uncompromising standards and requirements. Therefore, in 2013, Luxon LED designed and implemented a comprehensive lighting system for cold stores, freezers and unloading halls.

What has Zott achieved thanks to the modernization of lighting?

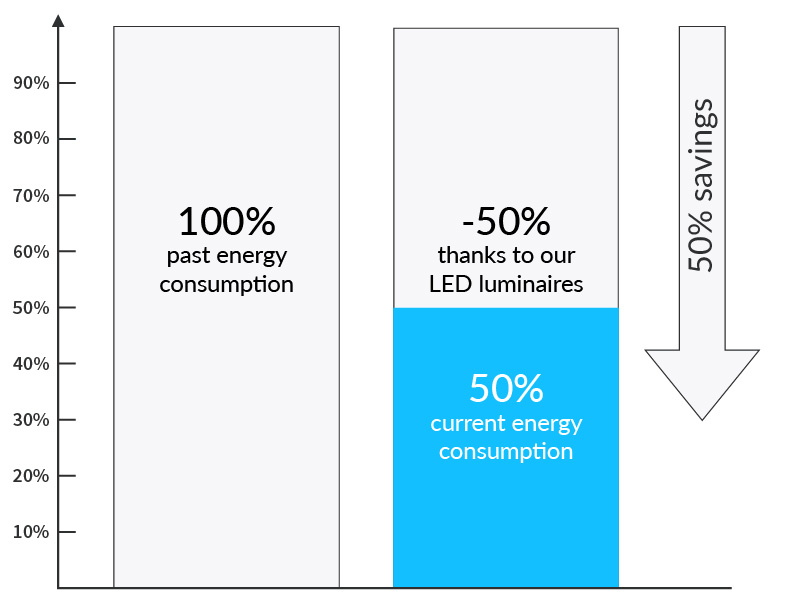

Electricity savings after modernization

Wireless lighting control system

60 months warranty

Warehouse of Zott company works everyday for many hours so it generates enormous costs. After substituting metal-halide lamps for Highbay:LED we are saving over 50% in electrical power expenses. Therefore, we are planning to introduce LED lighting in more applications.

Robert Szymczak

Zott Polska Sp. z o.o.

Challange

What luminaires can work in low temperatures?

The production process of dairy products requires appropriate storage conditions, especially low temperature in the halls such as cold stores and freezers. The luminaires we used had to be temperature-resistant in the range of 0 to 10 degrees Celsius. They also had to meet the standards of the National Institute of Hygiene (PZH). Our customer’s priority was to measurably reduce the costs of energy consumptions, increase the light quality and ensure failure-free operation of the entire lighting system. The luminaires had to be exceptionally leak-proof, have a high protection rating (IP) and cold colour temperature of 4000K – 6500K. Another goal of the project was to automate the lighting system in unloading halls. The Zott production plant was one of the first places in Poland where a wireless lighting control system was implemented.

Implementation and solution

Efficient high-IP luminaires and wireless control system

To design the system that meets our customer’s expectation and the effective standards in food production plants, we conducted an audit and familiarized ourselves with the building and the existing installation. We decided to replace 27 traditional HighBay 400W and 250W luminaires in cold stores and freezers with HighBay LED 120W and HighBay LED 180W with 6500K colour temperature and CRI>>70. In the lighting system for the production hall we used Industrial LED luminaires with OSRAM Duris E5 diodes with 4000K colour temperature and CRI>>85. We used the existing installation that was only 13 years old at the time and was in very good condition to limit the investment costs without losing the quality of the new lighting system. All luminaires met the client’s requirements regarding their longevity and ROI of <5 years.

What’s more, we changed 46 fluorescent lamps 2×58 and we created a wireless control system for them. We connected Industrial luminaires to controllers, using converters, the central unit, motion detector and daylight sensors installed in the halls where delivery trucks are unloaded. and daylight sensors installed in the halls where delivery trucks are unloaded.

Customer benefits

We have fulfilled all customer’s requirements

- Electricity savings of 50%

- Outstanding longevity of the luminaires

- Leak-proof luminaires with high resistance to low temperatures

- Intelligent wireless control system

- 5-year warranty for the luminaires

Implementation summary

50% energy savings

Implementation Gallery

Other Case Studies

Case study – Luxon and Indulux for the Grolsch brewery in the Netherlands

We have established cooperation with Indulux that included the delivery of LED luminaires to facilities belonging to Grolsch in the Netherlands. Reducing electricity consumption, caring for the environment and employees and the need to phase out fluorescent lamps were the main reasons why the company decided to replace its light sources.

Project in the KOMFORT HOME shop in Komorniki

What are the major challenges and needs for showrooms planning to purchase lighting? Find out more about the case study of our customer KOMFORT HOME. The shop, located in Komorniki, was fitted with modern and energy-efficient LED lighting.

Masz dodatkowe pytania?

Zapytaj naszego eksperta