Werner Kenkel Group is a Polish manufacturer of cardboard packaging. The company supplies corrugated cardboard, offset and digitally printed packaging and cardboard display stands to the international market. Werner Kenkel sp. z o.o. relies on its sustainable economic development policy and respect for the natural environment. Following these ideas, as well as in order to increase the comfort of employees in the production halls and in their immediate surroundings, new energy-efficient lighting based on LED technologyhas been installed.

Project video

Watch the video prepared by Hubert Świtała, our Business Development Manager

What benefits has the lighting replacement had?

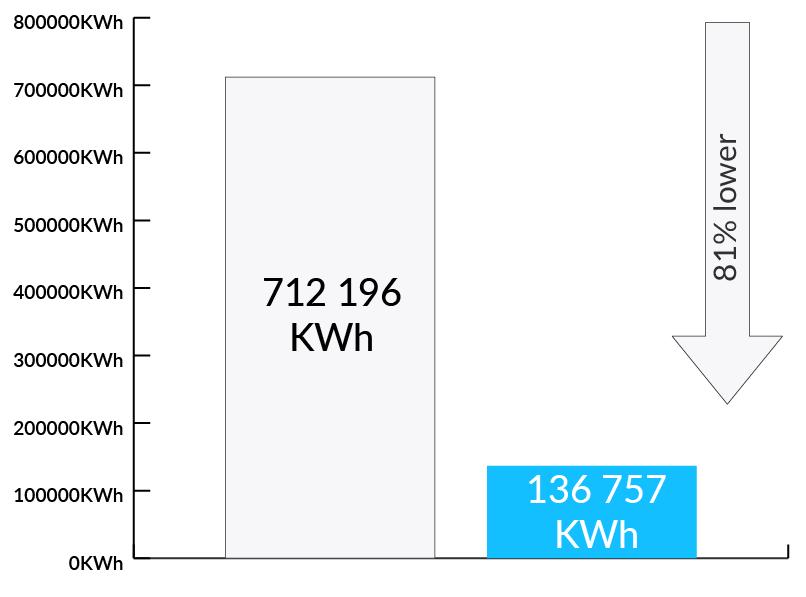

Reduction of 81% of the electricity used annually for lighting

10-year warranty for the luminaires

total return on investment in 2 years

By upgrading the lighting, we can reduce electricity consumption and adjust light intensity at all workstations and passageways.

Tomasz Janicki

Werner Kenkel

Compare the effect before and after – move the line in the middle of the photo

LED lamps as a source of savings

An important objective of the upgrade of the production hall lightingwas to ensure proper working conditions while reducing the use of electricity. Installation of modern LED lighting also involved the need to integrate it with the existing control system. In addition, the investor wanted the luminaires to be covered by a long-term warranty. The investor required the installation to be done without interfering with the production, it had to be performed with the plant running.

Comprehensive upgrade of lighting with the control system

The production hall lighting, and in particular of the workstations inside, must meet the requirementsrelating to employee comfort while performing their work. This has an immediate impact on productivity andwell-being of employees. For this purpose, we performed an audit and based on it we proposed LED Industrial 6.0 luminaires with tailoredspecifications. They improved the average lighting intensity in the work areas while ensuring the high energy-efficiency of lamps.

In addition, the replacement of the lighting system also included the areas around the building. In that area Cordoba 3.0 luminaires proved to be ideal.

Compare the effect before and after – move the line in the middle of the photo

The company is committed to delivering modern solutions, so as part of the upgrade project it was necessary to integrate the lighting system to the existing infrastructure layout. We used the lighting system based on reflected light sensors and integration with central monitoring of emergency lighting. As a result, we createdlighting scenes tailored to specific workstations, while reducing electricityconsumption.

New LED lighting of the production hall and its benefits:

- annual reduction in electricity consumption of 81%,

- short return on investment time,

- 2-fold increase of lighting intensity,

- energy-saving lighting control system using reflected light sensors,

- 10-year luminaire warranty,

- obtaining White Certificates,

- adjusting the lighting to the BMS system.

Through the lighting upgrade project, Werner Kenkel has improved working conditions and reduced electricity consumption, which resulted in a return on investment of less than 2 years.

Hubert Świtała

Business Development Manager

Industrial lighting upgrade – project summary

The broad-sense project in the facility of Werner Kenkel sp. z o.o. included the audit, design and installation of modern LED lighting. We have equipped the halls with over 400 Industrial 6.0 luminaires, and 27 Cordoba 3.0 parking lights. Investor benefits include:

Electricity savings

81% savings on annual electricity consumption for lighting

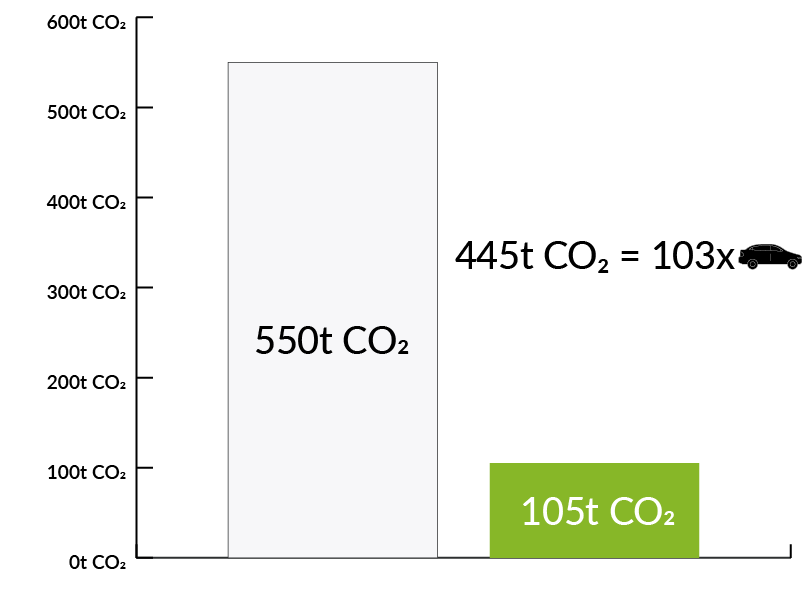

CO2 emission

Reduction of CO2 emissions by 81%

Do you want to find out what savings can be achieved by upgrading the lighting in your company? Contact us! We will perform a free audit and offer the most beneficial solutions.

See other Case Studies

Case study – Luxon and Indulux for the Grolsch brewery in the Netherlands

We have established cooperation with Indulux that included the delivery of LED luminaires to facilities belonging to Grolsch in the Netherlands. Reducing electricity consumption, caring for the environment and employees and the need to phase out fluorescent lamps were the main reasons why the company decided to replace its light sources.

Project in the KOMFORT HOME shop in Komorniki

What are the major challenges and needs for showrooms planning to purchase lighting? Find out more about the case study of our customer KOMFORT HOME. The shop, located in Komorniki, was fitted with modern and energy-efficient LED lighting.

Masz dodatkowe pytania?

Zapytaj naszego eksperta