Safran Transmission Systems Poland is one of the leaders of the aviation industry who has been manufacturing components for aircraft engines since 2001. The company cooperates with over 30 Polish suppliers and employs ca. 900 employees. The production process takes place in three large factories located in Poland. Skanska Company, the general contractor who created new buildings for Safran, asked us to work with them to select the appropriate lighting system for the new object built next to the existing production hall. After successful collaboration with Skanska company, we received a direct query from Safran, who asked us to modernize their existing lighting systems in older buildings. We carried out an audit and created a solution that met the expectations of the owner of these specialized production halls.

Video

Watch a video starring our client’s plant – Piotr Juszczyk Maintenance manager

What are the benefits of the project owner who uses our products and services?

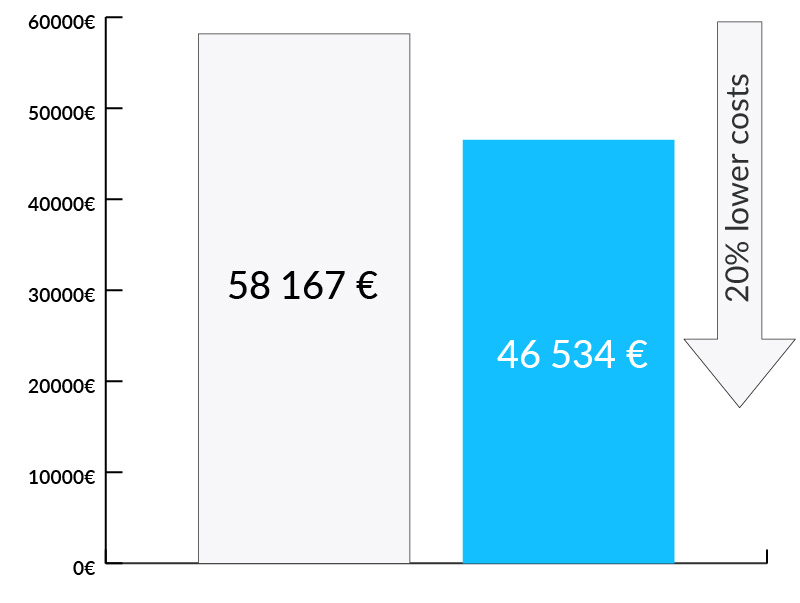

Reduction of electricity consumption costs across the whole company by 20%

Lighting in accordance with applicable standards, with a 10-year warranty

CASAMBI wireless control system

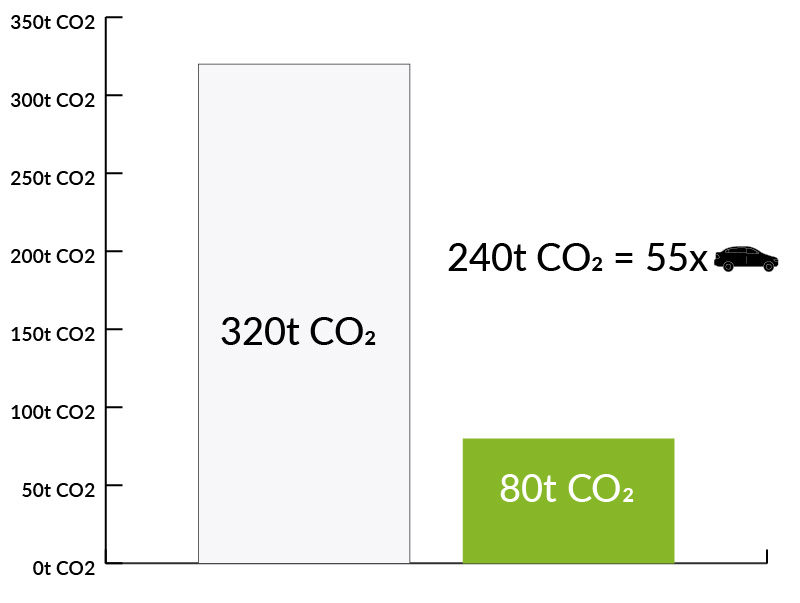

Thanks to the modernization of lighting, we were able to reduce carbon dioxide emissions by about 240 tons per year, and at the same time we managed to reduce costs due to electricity consumption by about 20%

Piotr Juszczyk

Maintenance manager

Challenges

Modernization of lighting using the existing wiring. What intelligent remote control system to use when the installation cannot be changed?

The lighting system for the new buildings was designed from scratch. However, when we were asked to modernize the existing ones in the older buildings, it was necessary to use the existing wiring system. The luminaires had to be installed using the already existing cable routes because of the round-the-clock work of employees and the location of machines. We also faced the challenge of implementing such a control system that would be wireless and intelligent to adapt the lighting mode depending on the operating conditions. The investor wanted to use efficient luminaires to optimize the energy consumption.

Implementation and solution

High-efficiency luminaires with low glare rating and Casambi wireless control system

We installed approximately 600 LED luminaires in the new buildings, using the Helvar control system. In the older halls with the existing cable routes we needed to keep, we used approximately 1500 luminaires and the Casambi module to increase the light intensity in certain areas of the production hall. The Casambi wireless control system allowed us to reduce installation costs because we didn’t have to use additional DALI wiring, so the production work was not interrupted by our installation procedures. We didn’t need a new signal cable. Each luminaire is controlled individually, and it is possible to change the lighting in specific areas, thus improving the working conditions according to the production requirements. The lighting parameters can be managed using a mobile device with a dedicated application. We installed also motion sensors that can be easily connected to the Casambi mobile application and assigned to specific luminaires. To achieve a lower glare rating and higher IP, we used such high-power luminaires as Ultima, Industrial, and Highbay.

Customer benefits:

- Significant reduction of energy consumption and lower operating costs

- A wireless control system that enables the user to adjust the parameters of the luminaires

- A 1:1 replacement of the luminaires without changing the existing electrical installation

- Improvement in light intensity of up to 300%

- 10-year warranty on the luminaires

- Lower UGR and improved working conditions

Download PDF

Other Case Studies

A turnkey lighting project and installation service for PRETTL Electronics GmbH

An increase in productivity and a reduction of CO2 are the key objectives set by the investor. Our solution was based on reducing energy consumption for lighting while increasing comfort to employees. We did this by uniformly illuminating the workplace areas.

Luxon LED to brighten up SWISS KRONO. A new sustainable and energy-efficient solution for the Żary-based manufacturer of wood-based materials.

Luxon LED has won a tender to improve energy efficiency at the plant of SWISS KRONO sp. z o.o., a company that is part of the Swiss holding SWISS KRONO Group, one of the world's leading manufacturers of wood-based materials. Nearly 4,500 luminaires in the Żary plant will be replaced, which will result in a reduction of energy consumption by 5,435 MWh per year.

Masz dodatkowe pytania?

Zapytaj naszego eksperta