In industrial lighting, the LED luminaires are often installed in harsh environments. The diversity of industries has to do with the multitude of factors that affect the quality and correctness of lighting systems. There are at least several of them. Given this, and taking into account the safety of workers, the lighting of such facilities should be adapted by the designer to the prevailing conditions. Keeping in mind that among the most important assumptions of a new system are the maintenance of the high parameters of the light sources as well as their reliability and energy efficiency, it is important to keep in mind what they may be exposed to. Therefore, in this article we highlight the following:

- factors affecting the performance of light sources,

- problems associated with the use of LED luminaires in harsh environments,

- design of lighting resistant to adverse environmental conditions.

LED lighting exposed to external factors

Large, high, industrial spaces are always a challenge for lighting designers. Areas with harsh conditions can be an added complication. Depending on the industry and the type of activities in a given facility, the factors affecting the failure rate of a lighting system can vary. These include

- harmful substances,

- risk of mechanical damage,

- high temperatures,

- high humidity.

Providing adequate lighting in the facility, at each workstation or the general lighting is essential. This guarantees the safety of work and the comfort of users. Note also that LED luminaires not only generate lower maintenance costs, with respect to conventional sourcess, but are also more resistant to diverse environmental conditions.

Where are LED sources most at risk?

One of the challenges of using LED luminaires in industry is the prevailing high temperature in buildings, reaching up to +70°C. This usually occurs in workplaces that have operating furnaces or other heat-generating equipment. These include, among others combined heat and power plants, steel mills, plants with injection moluding machines or induction furnaces.

Where the lighting system is exposed to mechanical damage? First of all, these are places where they can be physically knocked down or damaged. This risk is present in sports halls and street lighting, as well as in facilities with overhead cranes. Note that this can occur even in low-storage warehouses, where lighting can be damaged, even by a forklift.

Both, chemical substances and dust affect the failure rate of lighting systems made with LED technology. Luminaires used mainly in facilities where they require cleaning with special chemicals should be resistant to such factors. This applies to both the food industry and all kinds of livestock farms. In addition, in livestock facilities, there is an increased amount of harmful compounds in the air, such as ammonia, which can also adversely affect the durability of ordinary luminaires.

In such facilities, it is also important to keep in mind the direct effect of water, as well as its condensation. This is also the case of lighting located outside the building. In this case, the resistance of luminaires to environmental conditions and, in particular, to moisture condensation is important.

Inadequate lighting and problems arising from its use

Note that, in order for LED light sources to be properly matched to the space in which they will be installed, it is necessary to perform a lighting audit beforehand. Based on this, it will be possible to best assess the conditions that may adversely affect their performance.

Problems that can occur and their causes

What are the most common problems associated with the use of LED luminaires in harsh environments? These typically include:

- accelerated degradation of luminous flux

- change of colour and physical parameters of the component and body of the luminaire,

- higher failure rate of the power supply system,

- all kinds of cracks and corrosion causing product degradation,

- changes in the photometric solid.

These problems can generate insufficient illumination at workstations. This can result in higher energy consumption and, more rarely, electrical system failure.

The above problems and failures of LED lighting can occur for several reasons. An insufficiently detailed lighting audit is one of them. In this case, it is important to accurately diagnose the factors to which the LED light source is exposed. The designer, too, should pay close attention to all environmental aspects and adjust luminaires that will conform to their requirements.

LED luminaires in harsh environments

In areas exposed to external factors, LED luminaires perform far better than conventional light sources. However, it is important to remember to select them appropriately, depending on the prevailing conditions in the areas. This applies to the IP resistance, IK and the material from which the lighting was made.

Why do luminaires equipped with LEDs perform better?

This is because they usually have a more modern design, making them suitable for various applications. However, this applies only to properly designed light sources of high quality.

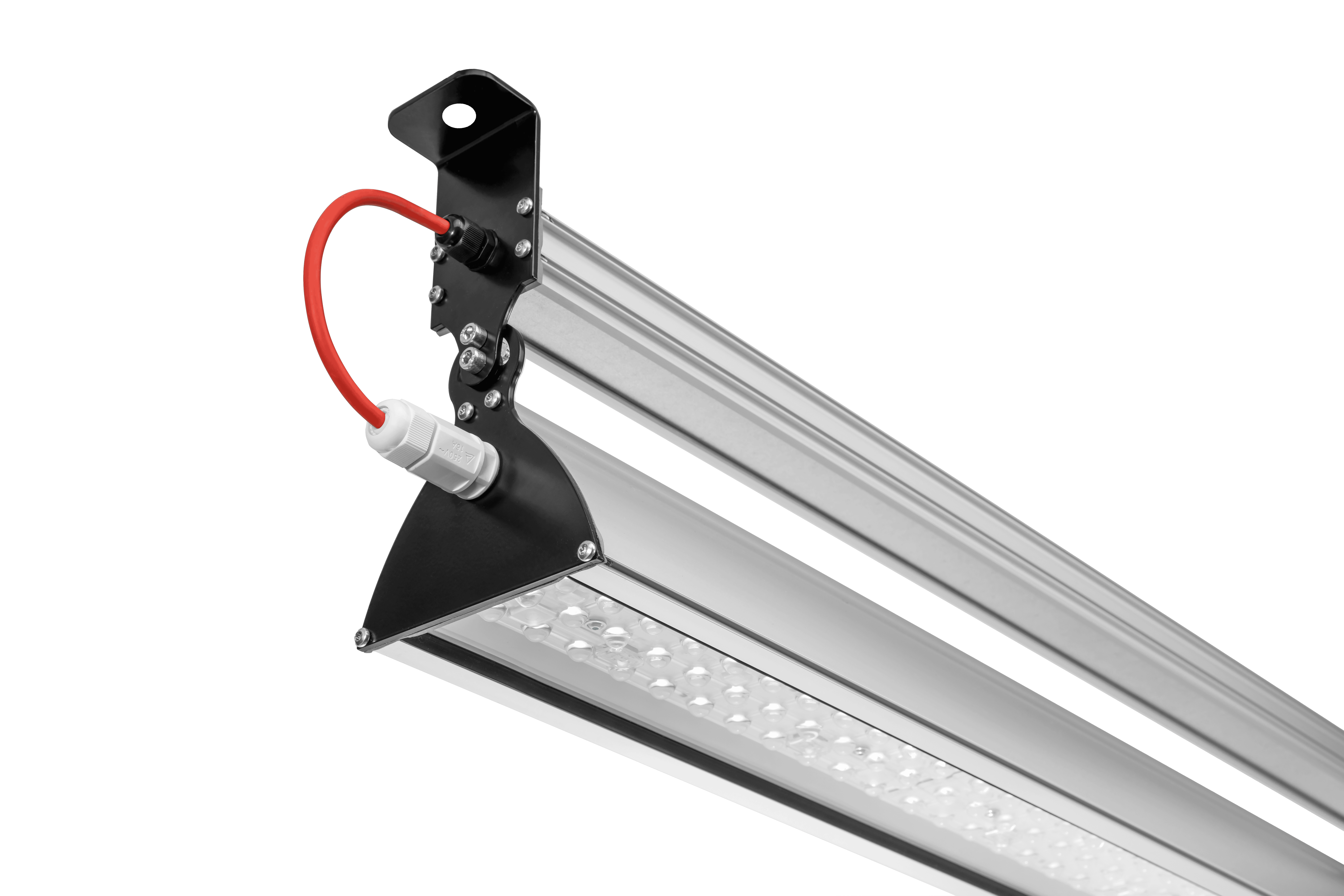

Luminaires operating in high ambient temperatures reaching up to +70°C should be equipped with LEDs and power supplies designed for this type of environment. Moreover, if the lighting is exposed to high temperatures, it is necessary to ensure proper thermal management in order to preserve the life of industrial lamps. This means that luminaires should have properly selected materials and properly designed construction. Such a product is, for example, Ultima LED HPT, which has a lightweight anodised construction.

Note that both, traditional incandescent and fluorescent lamps, due to the vapours produced when they fail, are increasingly rarely used in industrial facilities. Both, the resistance to mechanical damage and chemical substances is higher for luminaires made with LED technology. However, also in this case, it is necessary to select the appropriate components for it. Chemical agents and the light sources used, in which the LED as well as the entire structure will resist their adverse effects, have to be identified in advance.

If you are still wondering what LED luminaires to use in your enterprise, where lighting is exposed to a harsh environment, email us. Below you will find a form where you can ask us related questions. We will help you choose the right solution!

Do you have additional questions?

Ask our expert

See other articles

Lighting upgrade in Schumacher Packaging production plant

Schumacher Packaging is one of the largest European manufacturers of corrugated and solid cardboard packaging. The company offers its solutions to market sectors such as foodstuffs, chemicals, cosmetics, logistics and broadly defined e-commerce.

ZPS “Karolina” – manufacturer of unique porcelain

The Karolina production facility is a company with a 150 year old history of delivering porcelain serveware. The organization is ranked high among European manufacturers and their wares are widely recognized not only in the EU but also in the USA and Egypt. We've upgraded the lighting system in the whole facility, including the Quality Department which allowed to precisely rate the quality of each production batch.