De Facto offers a cutting-edge technology for cataphoretic coating of metal objects to protect them from corrosion. Moreover, the company runs a fully-automated industrial powder coating plant that allows for accurate and uniform coating of treated parts while maintaining the corrosion protection. In order to increase comfort work at the coating workstations and reduce the cost of electricity used for lighting, the investor decided to replace the luminaires. We offerred a lighting solution based on robust and energy-efficient lamps made with LED technology. Our design met all the requirements for luminaires in the coating plant, so the investor chose our offer to upgrade the lighting.

Compare the effect before and after – move the line in the middle of the photo

What has the investor gained by using our products and services?

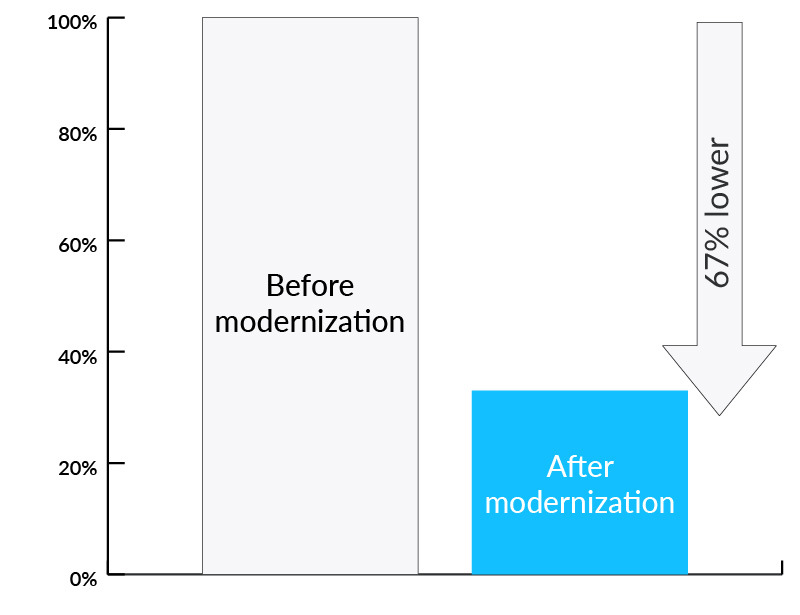

Reduction of electricity consumption by 67%

Three-fold increase in light intensity

Return on investment in less than 2 years

Compare the effect before and after – move the line in the middle of the photo

Challenges in the lighting retrofit project

Replacing luminaires in high temperature areas.

The task involved replacing inefficient fluorescent lamps with highly efficient LED sources at the powder coating workstations. Working furnace in the area made the indoor temperature much higher. That required installation of luminaires which could withstand the high temperatures at the ceiling. In doing so, we had to also remember that the painted surfaces should evenly illuminated .

Retrofitting of lighting in the powder coating plant – implementation and solutions

Choice of lamps for the coating areas.

In our design, we were aware that coating of metal elements requires great precision, hence higher light intensity. Considering the specific nature of the plant operation, we installed sealed Ultima LED HPTluminaires, which are designed for use in areas with high air temperatures, up to 70°C. With this solution, we have tripled the average light intensity at workstations. Ultima LED HPT is distinguished by a low level of glare, and this application made it possible to obtain high uniformity of lighting, which significantly improved comfort and quality of work at the workstations where the coatings are applied. We acomplished all that while reducing electricity consumption by 67% over the year.

Compare the effect before and after – move the line in the middle of the photo

Customer benefits:

- Perfect illumination of workplaces, 3-fold increase in average light intensity

- Increased employee comfort through the use of low glare light sources

- Adapting luminaires for use in elevated temperature conditions

- Savings of 67% thanks to use of modern Ultima LED HPT lamps

- Quick return on the investment

- 5-year warranty on the luminaires

We provided the investor with a solution that ensures outstanding lighting of the workplace. We proposed luminaires which can withstand elevated room temperatures while simultaneously reducing electricity consumption.

Hubert Świtała

Key Account Manager

Other Case Studies

A turnkey lighting project and installation service for PRETTL Electronics GmbH

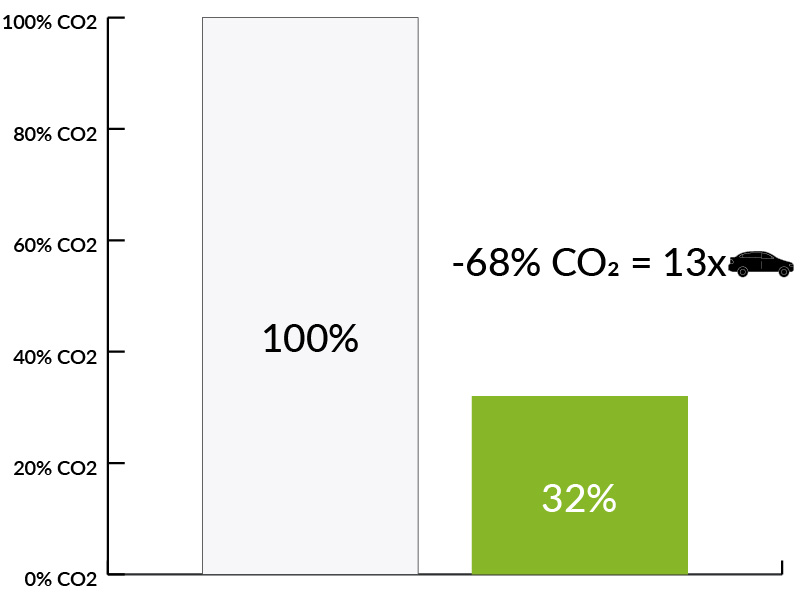

An increase in productivity and a reduction of CO2 are the key objectives set by the investor. Our solution was based on reducing energy consumption for lighting while increasing comfort to employees. We did this by uniformly illuminating the workplace areas.

Luxon LED to brighten up SWISS KRONO. A new sustainable and energy-efficient solution for the Żary-based manufacturer of wood-based materials.

Luxon LED has won a tender to improve energy efficiency at the plant of SWISS KRONO sp. z o.o., a company that is part of the Swiss holding SWISS KRONO Group, one of the world's leading manufacturers of wood-based materials. Nearly 4,500 luminaires in the Żary plant will be replaced, which will result in a reduction of energy consumption by 5,435 MWh per year.

Masz dodatkowe pytania?

Zapytaj naszego eksperta