The control of lights in a production hall is a solution that improves comfort and safety for employees while minimising energy consumption. State-of-the-art solutions are more and more often part of facility construction or upgrade projects. This is why it is worth getting deeper insights into:

- types of control solutions used with LED luminaires;

- possibilities of using lighting control solutions in upgrade projects;

- what lamp control in a production hall means in practice;

- what the potentialof LED control is.

Read the article below to find out more.

Lighting control solutions – types

Efficient light management in industrial facilities is quite a challenge. For this purpose, the use of LED light sources with integrated control systems is almost essential. Note that production halls are most often equipped with high bay luminaires, which can easily be connected to the lamp management system. Meanwhile, the luminaires can be controlled in various ways.

It can be one of the following systems:

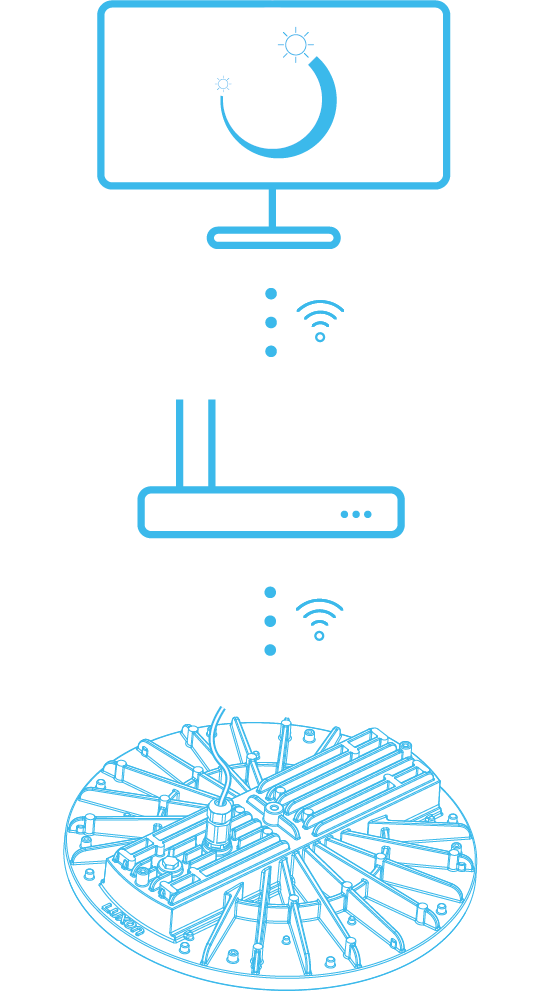

- wired, via a control cabinet located on site;

- wireless, from anywhere via networked peripherals;

and

- manual – the performance of luminaires is controlled by the user;

- automatic, when the luminaires operate according to a set schedule, for example.

Switching the lighting on and off as well as dimming can be done using different ways depending on which method is used.

Control system installation options while upgrading a hall lighting

The installation of a new lighting system in an existing facility must be preceded by a check of the wiring condition, even if it is planned to equip it with a control system. Lighting upgrade in a production hall is mostly based on new LED light sources which, when equipped with an additional module, can be controlled remotely.

The wireless control system has a number of advantages. These include, above all, its versatility, ease of installation and the possibility of expanding with new luminaires or groups of luminaires. The wireless control soultion requires no additional wiring, which is also worth considering. It can be installed very quicly and the luminaires can be replaced on a 1 to 1 basis.

Where is the wireless luminaire control system suitable?

| Controlled area | Control method | |

| Bluetooth | WiFi | |

| Production hall | v | v |

| Workstation | v | |

| Warehouse | v | v |

| Passageways | v | |

Wireless lamp control in a production hall – what does it mean in practice?

The control of lamps in a production hall is determined by the system installed. LED lighting used in a production plant equipped with a wireless control system is a convenient solution. It is controlled with a networking hub. This system makes it possible to manage the lighting of the facility from virtually anywhere in the world.

Moreover, the use of wireless technology makes it possible to combine luminaires into groups and control them collectively. This is particularly important when changing light intensity, e.g. in passageways and routes, as well as when it comes to warehouse lighting.

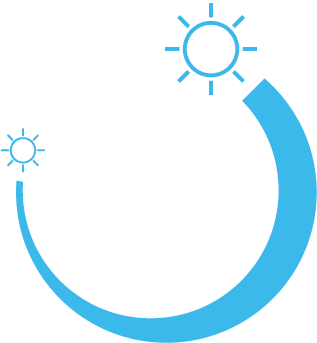

An unquestionable benefit of using a lighting control system in a production hall is energy efficiency. Based on data from daylight sensors, artificial light intensity can be adjusted automatically depending on the season or time of day. Furthermore, the light intensity level that should prevail in the hall can be determined wirelessly, e.g. in an application by a designated employee.

The potential of LED lighting control

The lighting system equipped with sensors is an opportunity for many additional functionalities. What is more, the wireless control of lights in a production hall allows unrestricted access to the managing employee. What functionalities are involved?

First of all, it is the dimming option, i.e. variable intensity – this can also be managed with system equipped with appropriate sensors measuring the amount of sunlight reaching the place.

A system equipped with motion sensors and presence sensors allows lighting to be switched on and off in spaces where employees are not present all the time. As a result, electricity consumption can be significantly reduced. Note that this does not adversely affect working comfort.

Wireless lighting control also allows you to measure the performance of the luminaire. These include measuring the temperature, operating time or power consumed by the LED luminaire. Based on the data obtained, it is possible to maintain a guarantee based on the real working time of the luminaire. This makes it easier to analyse operation or detect failures in the facility.

LED lighting in a production hall equipped with light sources connected to a control system can become a part of an intelligent building. Integration with the BMS (Building Management System) will allow efficient and cost-effective management of luminaires.

Would you like to find out more on wireless light control in a production hall? Contact us and we will answer all your questions.

Do you have additional questions?

Ask our expert

See other articles

What is discomfort glare?

Every one of us has, on more than one occasion, experienced dazzling light, which, in practice, is known as discomfort glare. Commonly referred to as glare, this effect adversely affects the eyes, reducing vision and recognition.

Lumens to watts – how to convert the luminous flux?

The luminous flux of LED lighting is given in lumens. With traditional light sources, on the other hand, the luminous intensity was usually determined as the power they consumed in watts. To be able to at least compare the two sources to some extent, it is necessary to convert lumens to watts. Therefore, in this article we address this issue.

Masz dodatkowe pytania?

Zapytaj naszego eksperta